THE CHALLENGE

- Hydraulic fracturing design generally addressed with simplistic models tempered by local experience.

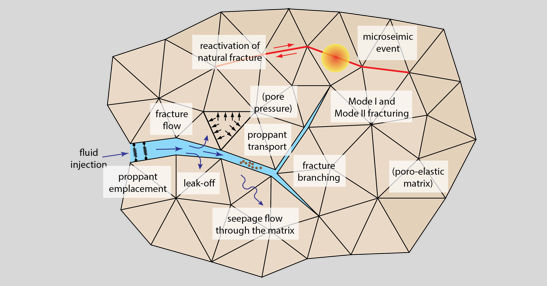

- Interactions between injected and existing fluids, in-situ and induced rock mass stresses, newly-created fractures, and natural discontinuities neglected.

- Failure to predict reservoir performance in response to changes in geomechanical conditions.

- Treatment and recovery inefficiencies, loss of wells, and lower return on investment.

THE SOLUTION

- Irazu is equipped with novel modelling capabilities for the stimulation and production of unconventional reservoirs:

- fully-coupled, hydro-mechanical solver including proppant transport and emplacement processes;

- incorporation of discontinuity surfaces and heterogeneities; and

- a fracture model accounting for tensile, shear, and mixed failure modes.

- Irazu enables accurate computation of stresses, strains, and fracture without minimal simplifying assumptions regarding fracture shape and growth trajectory.

THE RESULTS

- Optimize hydrocarbon extraction operations by numerically experimenting with injection rates, wellbore spacing, and fluid properties.

- Reduce drilling and production costs by predicting and optimizing the stimulation process.

- Evaluate the effectiveness of new stimulation methodologies and techniques, including the analysis of completion strategy, well spacing, and stress shadow effects.

- Increase safety by assessing hazards such as caprock integrity, wellbore damage, induced seismicity, and groundwater contamination.