By Jacob Andersen, CEO NaturaFrac Inc.

In the ever-evolving field of geomechanics, collaborations between industry leaders are pivotal in driving technological advancements. NaturaFrac’s work with Geomechanica exemplifies how synergistic efforts can lead to significant innovations in rock fracturing technology development. For almost every project with Geomechanica, Dr. Andrea Lisjak (numerical modelling lead and co-founder) has said “that has never been done before, but we think we can write some new code to enable what NaturaFrac needs.”

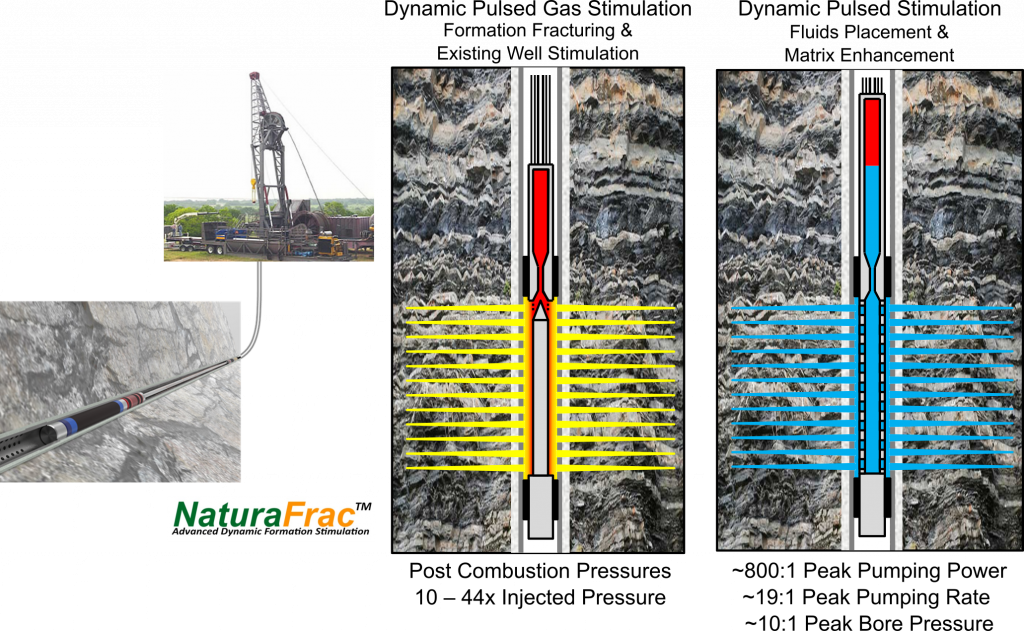

NaturaFrac is an energetics platform capable of providing a wide variation of pressurization events from a borehole to break down the surrounding rock formations. The markets NaturaFrac is developing solutions for include mining, geothermal, and oil and gas. With NaturaFrac’s novel capability for tuning fracturing treatments to various industry challenges, a flexible simulation capability is paramount. Some of the exciting applications under development include orebody preconditioning, tunneling stress/rockburst mitigation, in-situ recovery mining matrix creation and injection, and near-wellbore fracture geometry optimization to enhance hydraulic fracturing effectiveness.

Enhancing simulation capabilities with Irazu

Our journey with Geomechanica began with the integration of their Irazu simulation software into our research, development and testing processes. Irazu’s advanced modeling capabilities have been instrumental in simulating complex fracturing scenarios, allowing us to predict and analyze fracture behaviors with unprecedented accuracy.

Recognizing the unique challenges we faced, Geomechanica graciously collaborated closely with our team on each project to implement new features tailored to our needs with the following examples as demonstration:

Dynamic gas in fractures effects: Understanding gas propagation within fractures is crucial for optimizing NaturaFrac’s dynamic fracturing processes. Geomechanica enhanced Irazu to approximate propagating fracture combustion gas flow dynamics, providing deeper insights into fracture lengths and orebody/reservoir improvement potential. As our process can vary borehole pressure pulses applied to a formation by customizing peak pressure, strain rate, and pulse duration, access to a flexible and accurate dynamic fracturing simulation solution is paramount. The gas in fractures capability ensures we have a well-rounded modeling tool.

Discrete fractured formation block identification, characterization and statistics: Accurately identifying, characterizing and quantifying discrete blocks within complex fractured rock mass simulations is essential for assessing fragmentation performance for target applications such as deep stope preconditioning, bench blasting, cave mining, and even tunneling preconditioning, allowing us to optimize the blasting process for finer overall fragmentation and rockburst control. This will allow for greatly reducing required comminution energy in the milling process for mineral liberation. Geomechanica developed tools within Irazu to automate this process, enhancing our analytical capabilities and ability to fine tune fragmentation processes for more efficient mining.

Accurate dynamic material property modeling: Key to fragmentation optimization is the accurate modeling of the dynamic properties of rock masses during the fracturing process. Geomechanica integrated laboratory derived material properties and theoretical high strain rate behavior characteristics into the Irazu code to provide NaturaFrac with excellent correlation between experimental results and simulation predictions.

Large element count dynamic 3D fracturing simulations: Complex multi-material (elastic, non-linear and brittle) dynamic three-dimensional fracturing simulations requiring high resolution were performed by Geomechanica on their GPU hardware. This allowed NaturaFrac to directly simulate development/demonstration fracturing tests which allow validation and anchoring of the blasting design and simulation process.

These advancements have not only improved our simulation accuracy but have also streamlined our design and testing workflows, leading to more efficient project timelines.

Collaborative research and knowledge sharing

Our partnership extended beyond software and consulting services into essentially collaborative research endeavors. Co-authoring a journal submission allowed us to share our findings with the broader geomechanics community, fostering knowledge exchange and driving industry-wide innovation.

Geomechanica has also highlighted our joint efforts through their platforms, showcasing simulation results and technological developments. For instance, they shared a video demonstrating Irazu’s simulation capabilities in capturing complex fracture interactions, underscoring the practical applications of our collaborative work.

Looking ahead

The continuous evolution of rock fracturing technology relies on such strategic collaborations. NaturaFrac Inc. remains committed to working alongside Geomechanica Inc. to push the boundaries of what’s possible in dynamic geomechanical simulations, ensuring safer and more efficient resource extraction methods. With the accuracy the Irazu simulations have achieved to our experimental results, we can be confident in what our fracturing technology can accomplish in rock structures for the mining, geothermal, and O&G markets.

Jacob Andersen is the CEO of NaturaFrac, where he leads the company’s vision to transform how underground rock structures are stimulated using energetics. With a background in business and economics, Jacob has driven NaturaFrac’s growth through strategic partnerships, IP portfolio development, and industry engagement. He has played a central role in building a unique ecosystem of collaborators—from specialized consultants to research institutions—while guiding the company’s technology roadmap and long-term strategy. His focus remains on bridging innovation with practical deployment to address some of the toughest challenges in the subsurface energy and mining sectors.